Not without reason, HALBA attaches importance to its CO₂e strategy, as we need a lot of energy to produce our high-value foods. In order to reduce consumption and protect the climate, HALBA pursues the principle: avoid, reduce, offset (see Climate Protection Policy).

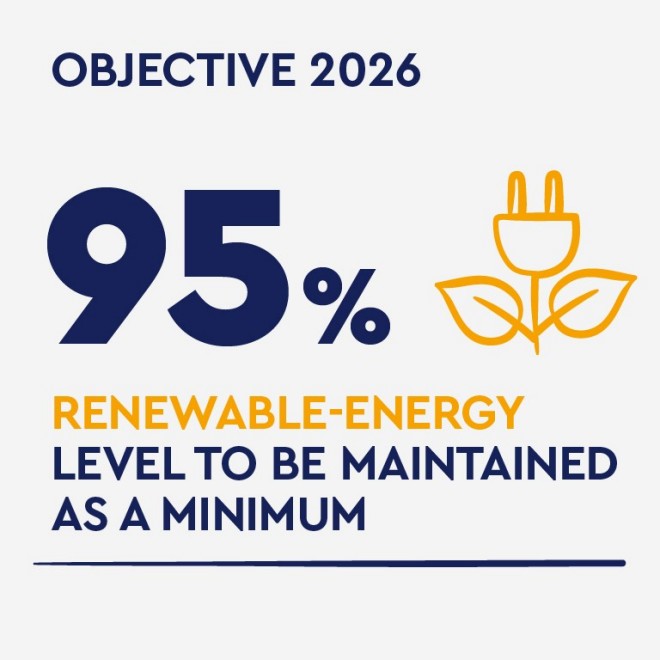

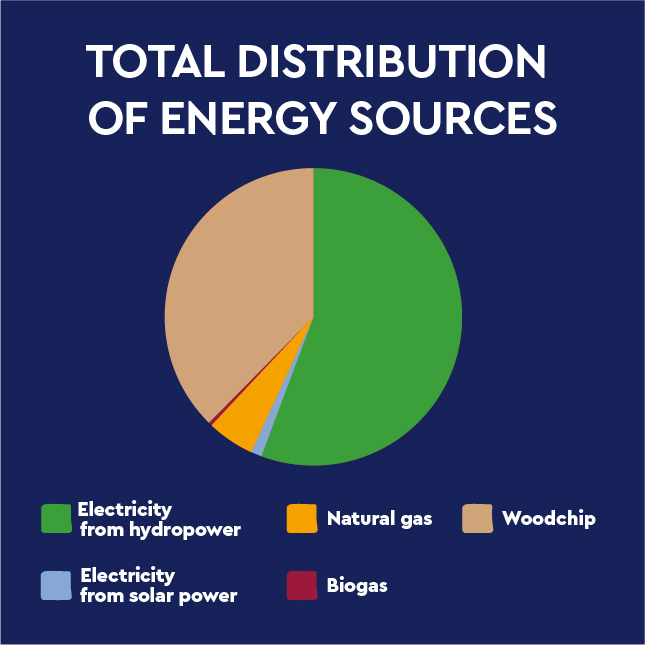

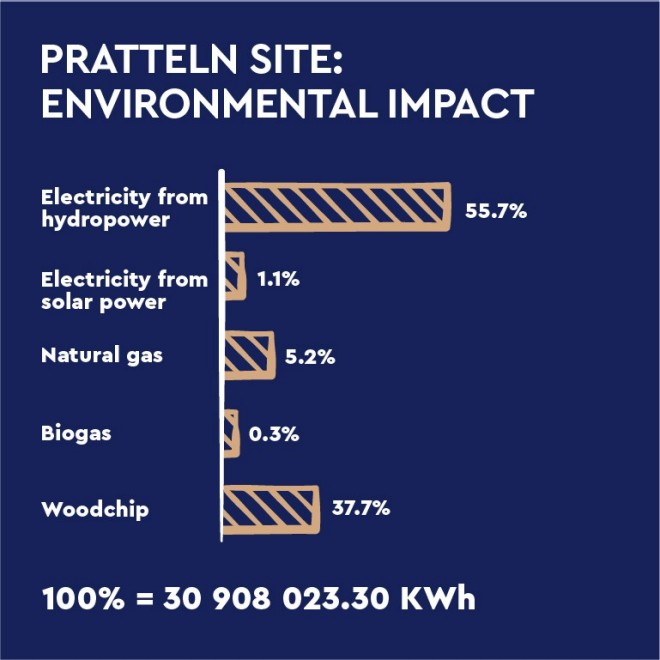

Within the context of production and energy, «avoid» means choosing processes that do not release CO₂e. For this reason, HALBA uses energy that is obtained almost exclusively from renewable sources for the Pratteln production site: electricity has been generated by hydroelectric power stations since 2011. Heat is produced from woodchip heating, and electricity from solar panels. A heat recovery system reduces waste heat. Natural gas is only used to roast nuts and to cover demand spikes, with the result that 95 per cent of the energy HALBA uses comes from renewable sources. In order to reduce the CO₂e footprint further still, HALBA plans to replace natural gas with climate-neutral biogas. At the same time, it is exploring the option of expanding its photovoltaic plant.

The company is also seeking to lower its reliance on airfreight (currently around 1 percent) even further and to choose alternative means of transport instead. HALBA has also set up an internal innovation group to identify more sustainable packaging materials. Since 2021, an environmental balance calculator has been used for packaging solutions.

Woodchip heating:

Woodchip heating is the main process used for generating heat for chocolate and for the site as a whole. Burning wood releases the amount of CO₂ that trees sequestered from the atmosphere whilst growing. As such, wood heating is practically carbon-neutral and does not contribute to the greenhouse effect.

HALBA is focusing on short transport routes in order to achieve even more of a positive impact on the climate balance: woodchip is obtained from sustainably managed forests within a radius of 50 kilometres from the site.

The plant in Pratteln generates 2 megawatts, thereby producing around 45 percent of heat energy including steam. This steam is used in production, amongst other things in order to roast and debacterialise cocoa beans. It is also used in the mass building to heat hot water to 95 degrees Celsius, which is then used for the conches, fat processing machines and the tank storage facility.

Solar power system:

In order to effectively use the building’s roof areas, a photovoltaic plant extending over about 8 000 square metres has been installed. This enables HALBA to support heat generation by the woodchip plant. The photovoltaic plant has a power output of 550 kWp. It produces 490 megawatt hours of solar-generated electricity each year, which is used directly on site. This roughly corresponds to the annual consumption of 150 detached houses.

In relation to production and energy, «reducing» means structuring and adjusting production processes so that they release less CO₂e – for instance, through energy efficiency measures.

In 2020, HALBA carried out a holistic analysis of all CO₂e-relevant process systems to identify the level of energy-saving potential. In 2022 an energy savings team was set up, comprised of six experts from the fields of processes, electronics, building technology and digitalisation. The team has the goal of recording the current situation and then assessing and implementing savings in energy consumption and CO₂e emissions.

The analysis and work carried out by the team of experts has already identified ten measures for increasing efficiency and reducing energy consumption. Three of these are described in greater detail below:

Heat recovery:

Certain process steps in chocolate production require warmth, for example heating the pipes that transport the cocoa mass. In order to do this, HALBA uses heat emitted by cooling machines. We are constantly seeking to raise our heat recovery rate in order to increase efficiency even further still.

We use the waste heat from our cooling systems amongst other things in order to heat office space. These systems also provide cold water for the site. The cooling process generates waste heat, which is collected via a heat exchanger. The energy thereby gained is fed through into the heating circuit. This could result in a minimum annual saving of 5 250 000 kilowatt hours of energy. In addition, HALBA uses the heat generated by computers or people in office areas. It is extracted by an air heat exchanger and then returned to the air intake, creating an additional heat cycle.

Cold management:

Certain process steps in chocolate production use cold air, including the cooling of chocolate and processing in kneading and stirring machines. By adapting the cold management system, HALBA has increased its production efficiency and thus sustainably reduced its energy consumption.

One example of this is the optimisation of cooling systems. These generate cold water for various temperature levels required in production as well as office air conditioning. In order to achieve energy savings consistently over time, the building technology team continuously analyses data in the building management system and aligns temperature levels with production. We have already been able to achieve a number of improvements in this way. These include raising temperature levels minimally during the production process, for instance increasing the room temperatures of cold-storage rooms, increasing temperatures in service rooms and isolating cold water pipes in the hydraulic unit.

Isolating process pipes:

Heated pipes are essential for producing chocolate: the chocolate conveyed within them needs to remain in liquid form in order to avoid clogging within the pipe. In order to avoid heat being lost by pipes, the pipes carrying water heated to 45 degrees Celsius are covered with a layer or insulating material, and thereafter with aluminium. This reduces the heat energy loss from pipes, and also means that rooms have to be ventilated less. This measure achieves a saving of 68 369 kilowatt hours per year in the unit’s production facility. A second production line has been insulated in the same way, and the same work is currently being carried out on a third line.

In the context of production and energy, «insetting» means balancing emissions. Some emissions are currently unavoidable within the HALBA production process. We ensure energy insetting for these emissions within our own value chain. We annually measure our operational CO₂e emissions for this purpose. The measured value is composed of operational emissions and emissions related to purchased energy. An independent external audit by myclimate verifies our calculations.

Fair offsetting. (see also "Good to know" in CO₂e -Strategy)

One example of the insetting of HALBA’s operational CO₂e emissions within its own value chain is the reforestation project in Peru. Approximately four trees must be planted to inset one tonne of CO₂. HALBA has planted 427 069 trees since 2011. This amounts to an average of 99 trees a day, and each and every one of them can be located through GPS tracking. This means that HALBA has inset around 91 714 tonnes of CO₂ in the past 11 years.

Verified Carbon Standard:

The Verified Carbon Standard is one of the world’s most widespread standards for verifying CO₂e offsetting projects. CO₂e offsetting projects compensate for greenhouse gas and CO₂e emissions.

Carbon Neutral Product:

Before a product can be deemed carbon-neutral, the amount of CO₂e emitted as a result of cultivating, transporting, producing and consuming it and disposing of its packaging is calculated. In the case of carbon-neutral products, the calculated amount of CO₂e generated is inset, for example through reforestation projects.

myclimate:

myclimate verifies and calculates the carbon footprint of companies and climate-neutral (or: carbon-neutral) products.